3.5 Challenges in modern aerostructures

3.5.1 Sandwich structures and composite materials

- High stiffness with low weight material configuration

- Core carries the shear load which the face sheets carry the tensile and compressive loads associated with bending

- Early example of sandwich structure was De Havilland Mosquito which had balsa core sandwiched between spruce face sheets

- Carbon and boron fibers are commonly used face sheets due to high specific stiffness and specific strength

- Core is often constructed of foam with high compressive strength

- Core and face can be adhesively bonded or molded in place

- Other cores are corrugated metals or metallic foams

- Early composite aircraft was the Raytheon/Beach Starship 2000 (1986)

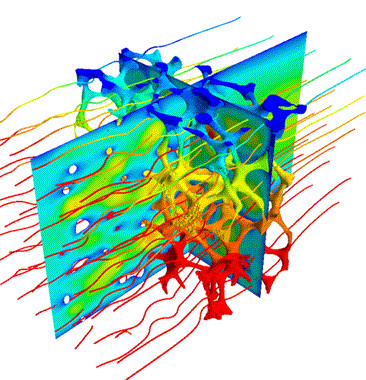

Metalic foams permit shear loads to be carried by a low density (porous) structure.

Blanchet matthieu, CCSA3.0, 2012

It also may serve multiple functions, ie, cooling

Jean-Michel Hugo, CCSA3.0, 2012

3.5.2 Tailored stiffness–composite materials

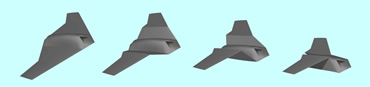

- Aeroelastic tailoring: use of directional differences in properties to carry load and cause intentional deformations that have aeroelastic advantages (stiffer in one mode of deformation than another)

NASA

- Grumman X-29A–Forward swept wing with aeroelastic tailoring.

- The advantage is that the wing tips stall last instead of first, allowing greater control

- Downside is that the aeroelastic deformation causes positive feedback on wing loading (wing loading drives higher angles of attack, drives higher wing loading)–Divergence

- Bend/twist coupling allows minimization of divergence effects

3.5.3 Wing warping

@TAMU2014

@TAMU2014

Challenges

- Maintain structural integrity during large changes in configuration

- Control