3.4 Historical background

Examples from: Dr. Jim Jastifer, 2010

3.4.1 Prelude

A flea the size of a man could jump about?:

- 1 meter

- 10 meter

- 100 meter

3.4.2 Galileo’s scaling problem

@Galilei1638

Galileo was among the earliest to document the sizing problem

"Who does not know that a horse falling from a height of three or four cubits will break his bones, while a dog falling from the same height or a cat from a height of eight or ten cubits will suffer no injury? … and just as smaller animals are proportionately stronger and more robust than the larger, so also smaller plants are able to stand up better than the larger.

I am certain you both know that an oak two hundred cubits high would not be able to sustain its own branches if they were distributed as in a tree of ordinary size; and that nature cannot produce a horse as large as twenty ordinary horses or a giant ten times taller than an ordinary man unless by miracle or by greatly altering the proportions of his limbs and especially his bones, which would have to be considerably enlarged over the ordinary"

As J.B.S. Haldane put it in his classic essay “On Being the Right Size”:

“You can drop a mouse down a thousand-yard mine shaft; and, on arriving on the bottom, it gets a slight shock and walks away… A rat is killed, a man broken, a horse splashes.”

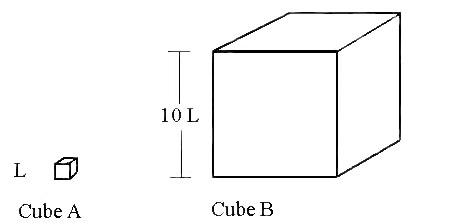

Cube \(B = 10 \times\) Cube \(A\)

- Bone strength is proportional to cross sectional area of the bone (\(L^2\))

- Weight is function of volume (\(L^3\))

- Relative strength decreases inversely with length scale (\(L^{-1}\))

Strength ratio based on dense scaling, (ie area/volume ratio).

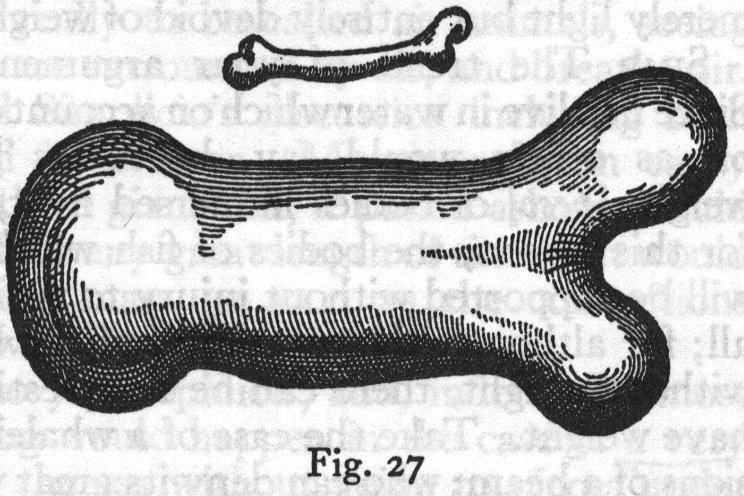

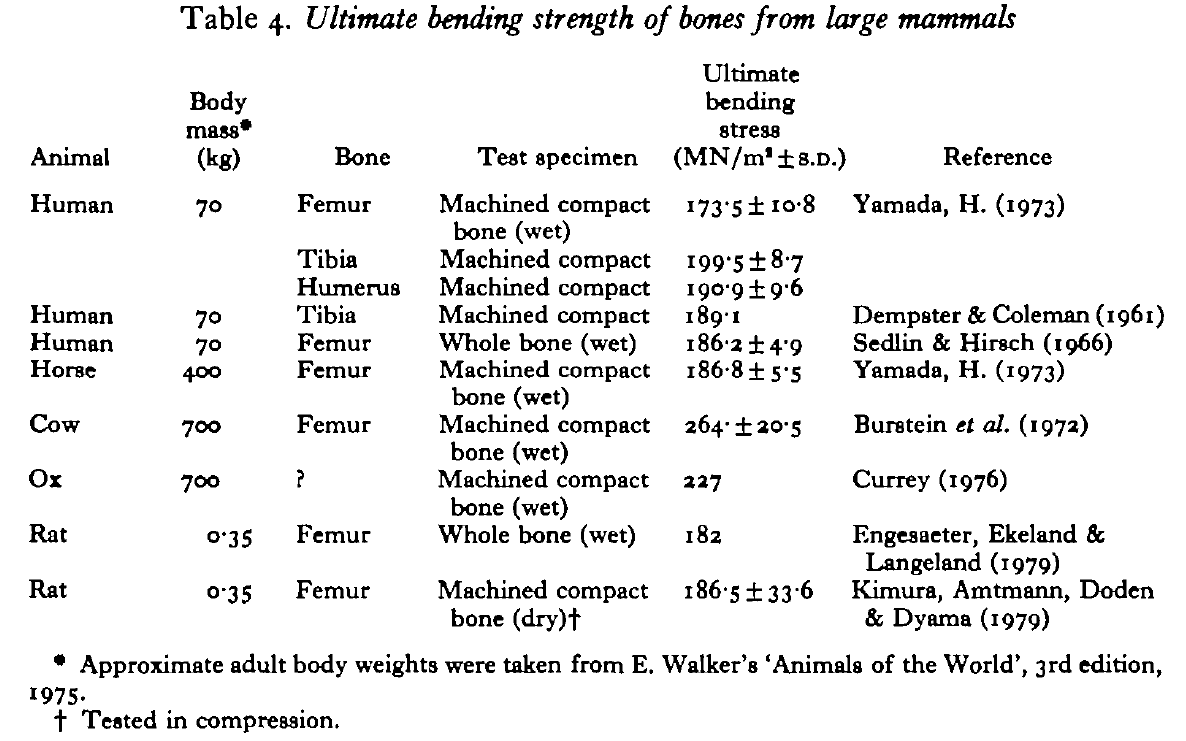

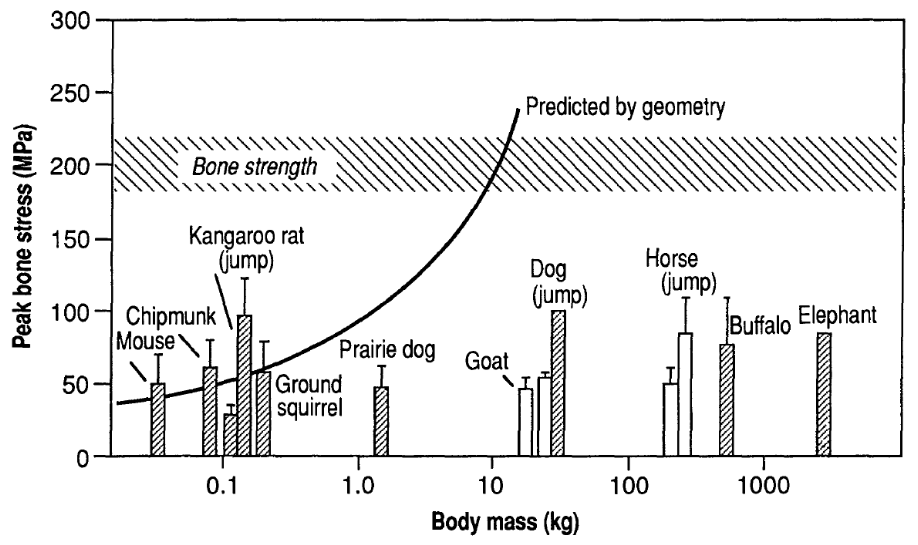

Human bone strength

@Biewener1982

- Rats, Humans, and Cows have similar bone strengths

Andrew Biewener

- With scaling, eventually, an animal’s bones will break under its own

weight.

- Gait and activity level matter.

- Larger animals tend to move much slower

Analogies in structural mechanics

- Historical building structures have similar limitations

- Does the above principal apply in Aerospace Engineering?

- Yes and No

- Aerodynamic scaling laws and aircraft sizing also come into play

- Larger tends to be better for efficiency, longer distances requires exponential fuel increases

- Structural weight scales at somewhat less than length\(^3\) in Aerospace (the volume contained is often empty).

- Yes and No

- Materials/structures can have size effects and flaws which dictate complex outcomes (larger isn’t generally better)

- Aerostructures (and structures in general) also limit activity

based on size

- Compare maneuvers conducted by a B747 to an Extra 300 or a RC aircraft

Staff Sgt. Efren Lopez, U.S Air Force, Public Domain, 2005

3.4.3 Aero structures history

Early flight: The Wright Brothers

@Daniels1903

First flight

- Dec 17, 1903

- 120 ft in 12 seconds

- Principal features

- Wood (spruce and bamboo)

- Fabric skins on ribbed wings

- Piano wire, rods, metal fittings

- Enabling technologies

- wind tunnel testing for improved airfoils and propellers

- rudimentary understanding of aerodynamics

- improvements in flight controls

- use of wing warping and canard

- tested on kites and gliders

- improvements in internal combustion engines

- significant advantage in power to weight ratio over steam engines and other alternatives

- wind tunnel testing for improved airfoils and propellers

- Note: our remaining discussion and this course will largely ignore improvements in aerodynamics

3.4.4 Truss structures in early airframes

- Allowed high stiffness to weight ratio

- Were based on civil engineering bridge structures

- This characteristic was necessary given the engine specific power available

- Structurally an advantage over the predecessors which modeled bird and bat-like structures

- Biplane configuration allowed for additional lifting surface area

- Thus, a reduction of induced drag – dominant drag at higher lift coefficients needed for low speeds

- Allowed control-ability through varying tension in the bracing wires

- Useful for wings (biplane) and for fuselage

- Wing coverings were muslin (lightweight cotton cloth in a plain

weave)

- Fabric was on the bias (45 degrees to the spar) and helped carry drag and inertial loads

- Primary structures were primarily of wood

This arrangement became the “standard” for several years

Early monoplane

Wikipedia commons

- Development of the fuselage was one of the next big advancements.

- Pilot and accessories no longer need sit right on the wing

- Low winged monoplane allowed energy absorption to occur below the pilot and passengers

Early monoplane

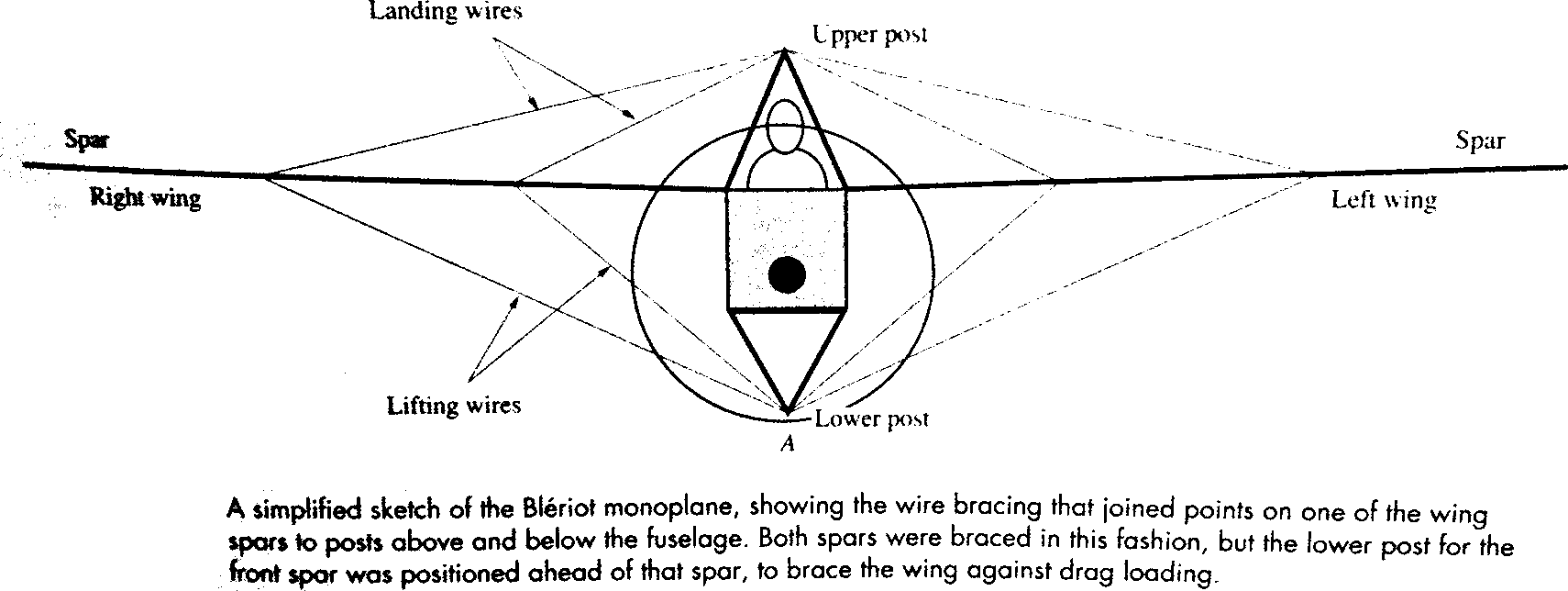

@Curtis1997

- Airfoils were still thin…

- Spars were not designed to carry lifting loads on their own

- Wires above and below the fuselage aided in carrying landing loads

Early monoplane

- Is there a downside to wire bracing? Yes!

- Compression and buckling failure due to the load component that is parallel to the wing

- Drag

- Internal wire bracing (inside the wing) was eventually employed

- Strength and durability were principal concerns with internal bracing

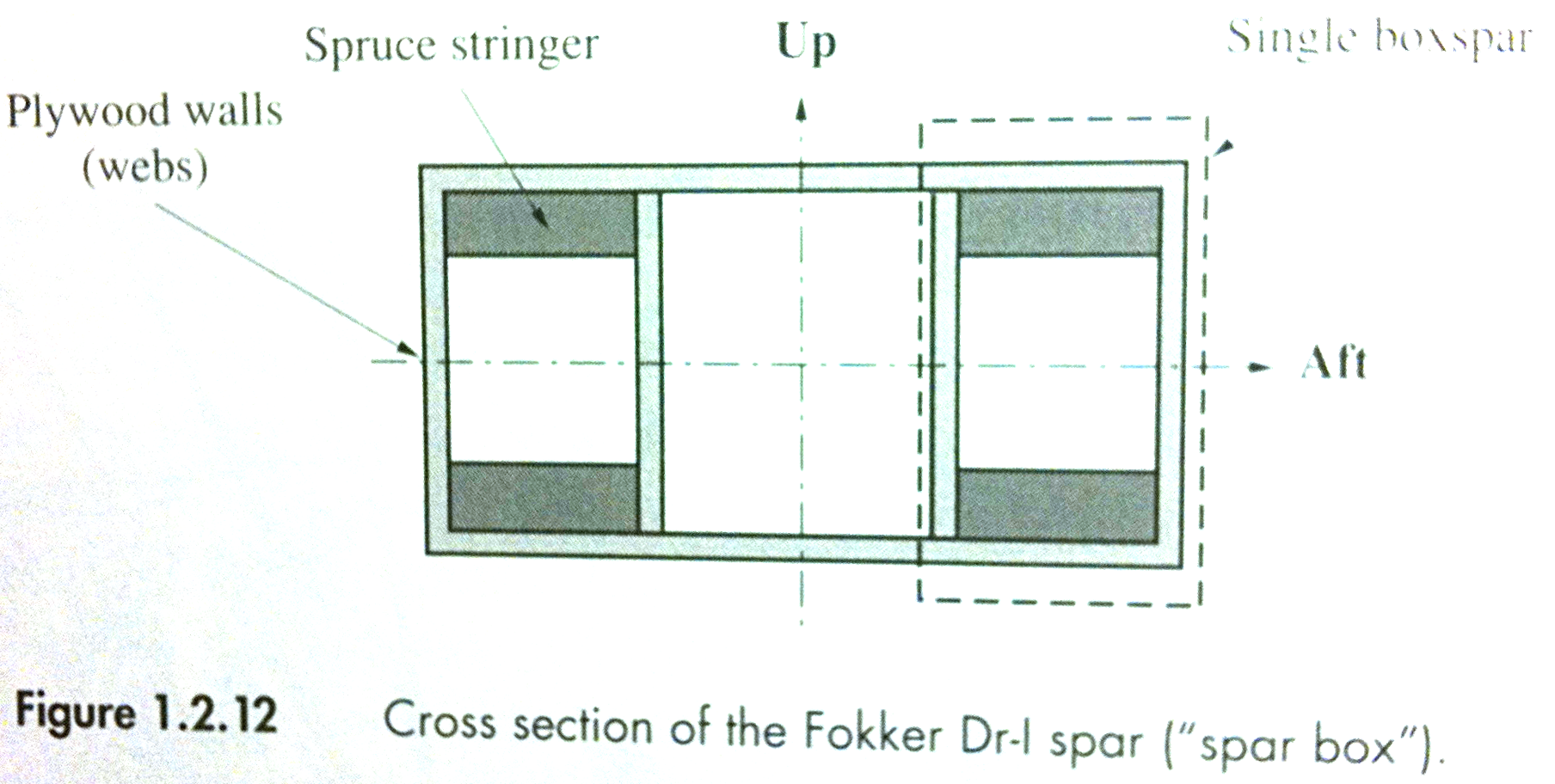

3.4.5 Cantilevered wings

David Merrett, 2007 CCSA2.0

- Cantilevered spars eliminated drag, no bracing (internal or external)

- Earliest practical version was the Fokker Dr-1 1912

- Spar box (plywood web with spruce stringer)

@Curtis1997

- Structural skins were used on wing and fuselage

- Planes were still multi-wing (triplane) – increased surface area and decreased bending moments

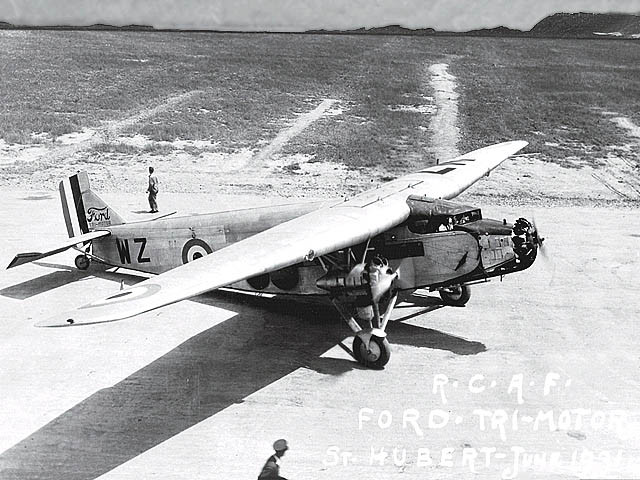

3.4.6 Metallic aircraft

Metallic aircraft represent a maturing technology

Royal Canadian Air Force, 1931

- Early metallic designs mimicked the existing wood truss structures

- Wing and fuselage coverings did not carry much load, were still made of muslin or plywood

- First practical all metal aircraft was the Junkers J-1 monoplane, 1915

- 1930s – Metallic skins began to be used. Corrugated skin added durability, however did not carry much load

Tri motor skin2

- Arguments in favor of metal:

- Manufacturing synergies with automobiles, etc

- “Fire resistance”

- Consistent/predictable material properties

- Limited supply of spruce after WWI

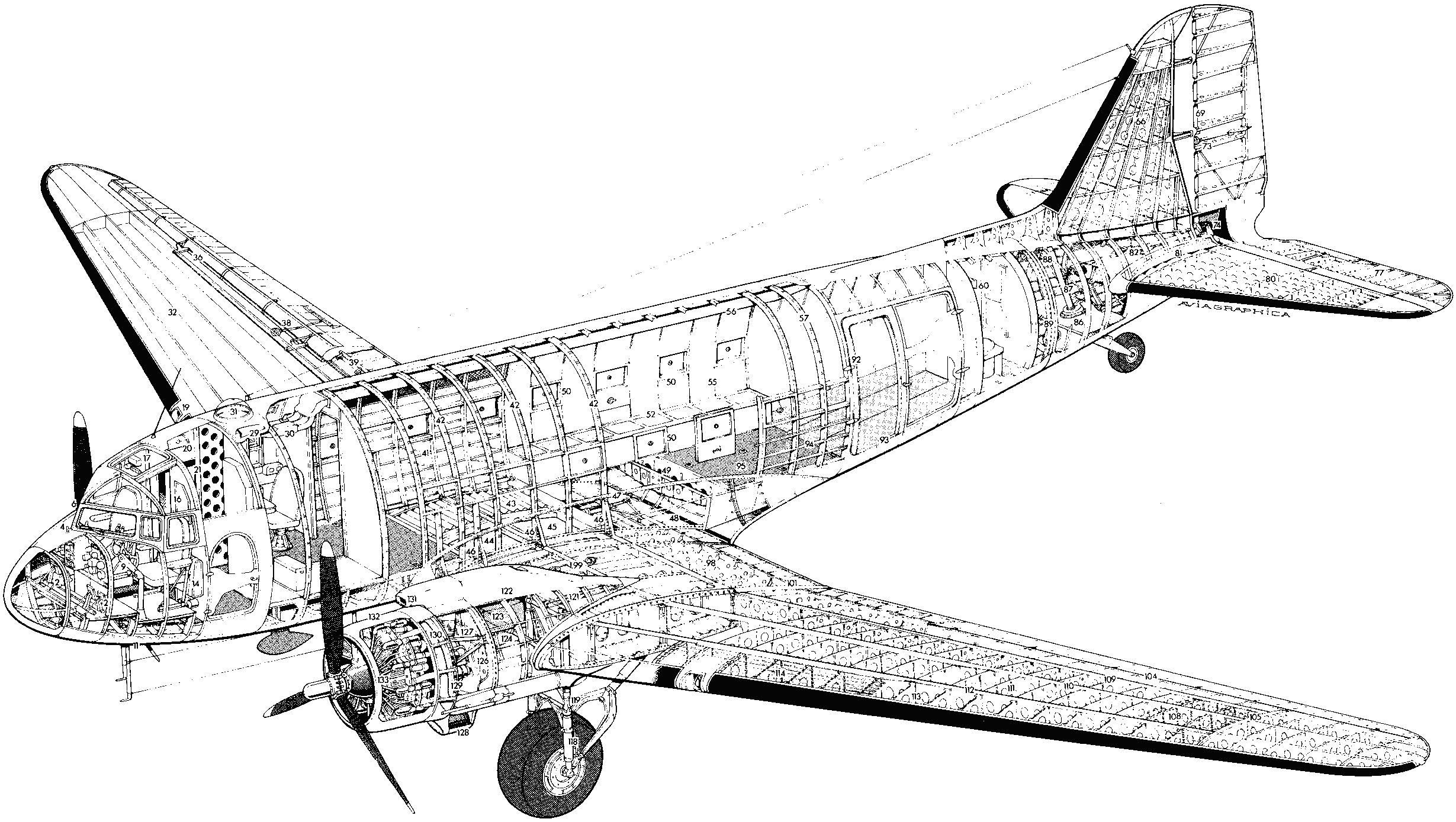

3.4.7 Monocoque Structures

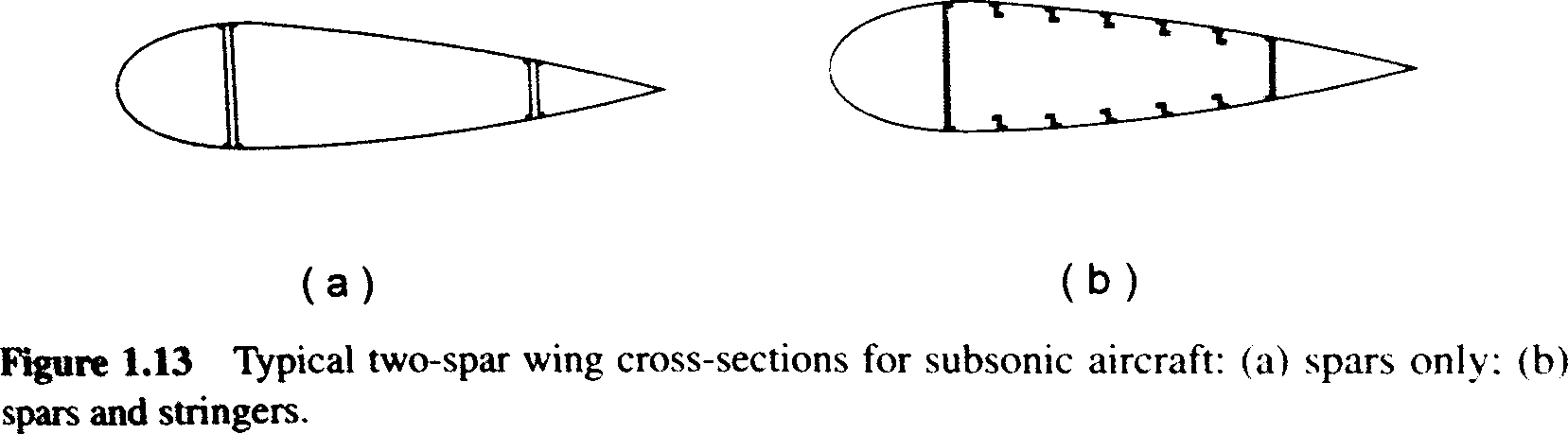

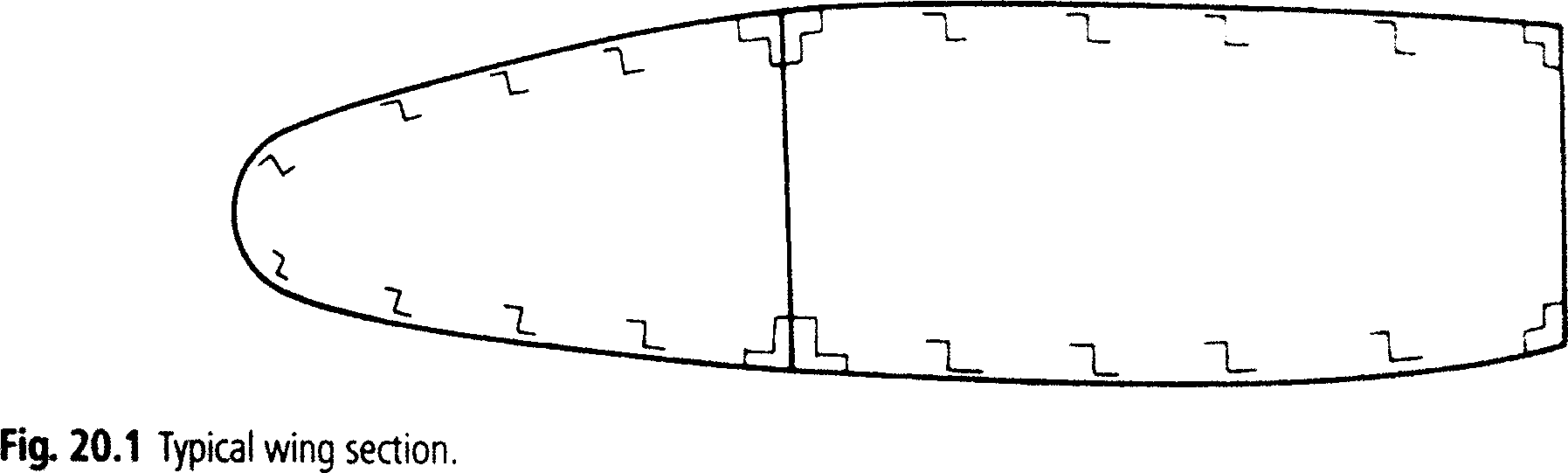

- Smooth metal skins–flush riveting

- Multiple spars arranged in cells

- Both are also called stressed-skin

- Monocoque–Thin curved walls and shells that carry load without need for support structures

- Semi-monocoque–similar to monocoque but has additional structural support – this became standard

- Nearly all modern metallic aircraft employ these design elements

3.4.8 Modern transport aircraft

Public Domain, LukaP, Wikipedia

- Boeing 707: Deliveries taken from 1958–1994

Spaceaero2, 2011, CCSA3.0

- Boeing 787: Deliveries taken from Sept 2011–??

- Pressurized fuselage allowed for a more comfortable 8000ft cabin pressure

- Circular fuselage is essentially a pressure vessel for efficient maintenance of cabin pressure

- Cutouts such as windows and doors caused stress concentrations and

fatigue cracks. Rounded corners were employed.

- De Havilland Comet was the first major tragedy associated with low cycle fatigue cracking

- Pressurized cabins and metallic load bearing structures ushered in an era where fatigue was a dominant concern of the structural designer

GFDL1.2 Wikipedia user W4kda↩︎