The single crystal model of Georges Cailletaud and co-workers

[50][51] describes infinitesimal viscoplasticity in metallic

components consisting of one single crystal. The orientations of the

slip planes and slip directions in these planes is generally known and

described by the normal vectors

![]() and direction

vectors

and direction

vectors

![]() , respectively, where

, respectively, where ![]() denotes one of

slip plane/slip direction combinations. The slip planes and slip

directions are reformulated in the form of a slip orientation tensor

denotes one of

slip plane/slip direction combinations. The slip planes and slip

directions are reformulated in the form of a slip orientation tensor

![]() satisfying:

satisfying:

| (270) |

The total strain is supposed to be the sum of the elastic strain and the plastic strain:

| (271) |

In each slip plane an isotropic hardening variable ![]() and a kinematic

hardening variable

and a kinematic

hardening variable ![]() are introduced representing the

isotropic and kinematic change of the yield surface,

respectively. The yield surface for orientation

are introduced representing the

isotropic and kinematic change of the yield surface,

respectively. The yield surface for orientation ![]() takes the form:

takes the form:

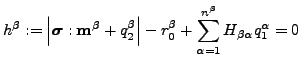

|

(272) |

where ![]() is the number of slip orientations for the material at

stake,

is the number of slip orientations for the material at

stake,

![]() is the stress tensor,

is the stress tensor, ![]() is the

size of the elastic range at zero yield and

is the

size of the elastic range at zero yield and

![]() is a

matrix of interaction coefficients. The constitutive equations for the

hardening variables satisfy:

is a

matrix of interaction coefficients. The constitutive equations for the

hardening variables satisfy:

| (273) |

and

| (274) |

where

![]() and

and

![]() are the hardening variables

in strain space. The constitutive equation for the stress is

Hooke's law:

are the hardening variables

in strain space. The constitutive equation for the stress is

Hooke's law:

| (275) |

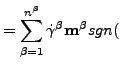

The evolution equations for the plastic strain and the hardening variables in strain space are given by:

|

(276) |

|

(277) |

and

The variable

![]() is the consistency coefficient known

from the Kuhn-Tucker conditions in optimization theory

[45]. It can be proven to satisfy:

is the consistency coefficient known

from the Kuhn-Tucker conditions in optimization theory

[45]. It can be proven to satisfy:

| (279) |

where

![]() is the flow rate along orientation

is the flow rate along orientation

![]() . The plastic strain rate is linked to the flow rate along the

different orientations by

. The plastic strain rate is linked to the flow rate along the

different orientations by

|

(280) |

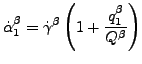

The parameter

![]() in equation (278) is a

function of the accumulated shear flow in absolute value through:

in equation (278) is a

function of the accumulated shear flow in absolute value through:

| (281) |

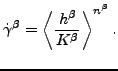

Finally, in the Cailletaud model the creep rate is a power law function of the yield exceedance:

|

(282) |

The brackets

![]() reduce negative function values to zero

while leaving positive values unchanged, i.e.

reduce negative function values to zero

while leaving positive values unchanged, i.e.

![]() if

if ![]() and

and

![]() if

if ![]() .

.

In the present umat routine, the Cailletaud model is implemented for a

Nickel base single crystal. It has two slip systems, a octaeder slip

system with three slip directions ![]() in four slip planes

in four slip planes

![]() , and a cubic slip system with two slip directions

, and a cubic slip system with two slip directions ![]() in

three slip planes

in

three slip planes ![]() . The constants for all octaeder slip

orientations are assumed to be identical, the same applies for the

cubic slip orientations. Furthermore, there are three elastic

constants for this material. Consequently, for each temperature 21

constants need to be defined: the elastic constants

. The constants for all octaeder slip

orientations are assumed to be identical, the same applies for the

cubic slip orientations. Furthermore, there are three elastic

constants for this material. Consequently, for each temperature 21

constants need to be defined: the elastic constants ![]() ,

,

![]() and

and ![]() , and a set

, and a set

![]() per slip system. Apart from these constants

per slip system. Apart from these constants ![]() interaction

coefficients need to be defined. These are taken from the references

[50][51] and assumed to be constant. Their values

are included in the routine and cannot be influence by the user

through the input deck.

interaction

coefficients need to be defined. These are taken from the references

[50][51] and assumed to be constant. Their values

are included in the routine and cannot be influence by the user

through the input deck.

The material definition consists of a *MATERIAL card defining the name of the material. This name HAS TO START WITH ''SINGLE_CRYSTAL'' but can be up to 80 characters long. Thus, the last 66 characters can be freely chosen by the user. Within the material definition a *USER MATERIAL card has to be used satisfying:

First line:

Following lines, in sets of 3:

First line of set:

Repeat this set if needed to define complete temperature dependence.

The crystal principal axes are assumed to coincide with the global coordinate system. If this is not the case, use an *ORIENTATION card to define a local system.

For this model, there are 60 internal state variables:

These variables are accessible through the *EL PRINT (.dat file) and *EL FILE (.frd file) keywords in exactly this order (label SDV). The *DEPVAR card must be included in the material definition with a value of 60.

Example: *MATERIAL,NAME=SINGLE_CRYSTAL *USER MATERIAL,CONSTANTS=21 135468.,68655.,201207.,1550.,3.89,18.E4,1500.,1.5, 100.,80.,-80.,500.,980.,3.89,9.E4,1500., 2.,100.,70.,-50.,400. *DEPVAR 60

defines a single crystal with elastic constants

![]() , octaeder parameters

, octaeder parameters

![]() and cubic parameters

and cubic parameters

![]() for a temperature of 400.

for a temperature of 400.